The number twelve (doze, dvanaest, twaalf, tolve) is significant and ubiquitous.

It's the number of months in a year, hours on a clock face, and the number of members on a typical court jury. It is mentioned in the New Testament of the Bible, including Jesus' selection of 12 apostles. The Greeks worshipped 12 major gods of Olympus. The significance of number 12 is visible elsewhere as well - from a dozen eggs to the 12 ribs on the average human to the 12 inches that comprise a foot.

We can go on, but we made the point, did we not?

We take you behind the scenes of how we make our cylinder valves, no marks for guessing – divided into twelve processes, each as important as the other (okay, we have a few favourites but let's keep it secret for the sake of this theme).

We invite you to visit us to see the manufacturing in action, all under one roof.

1

1

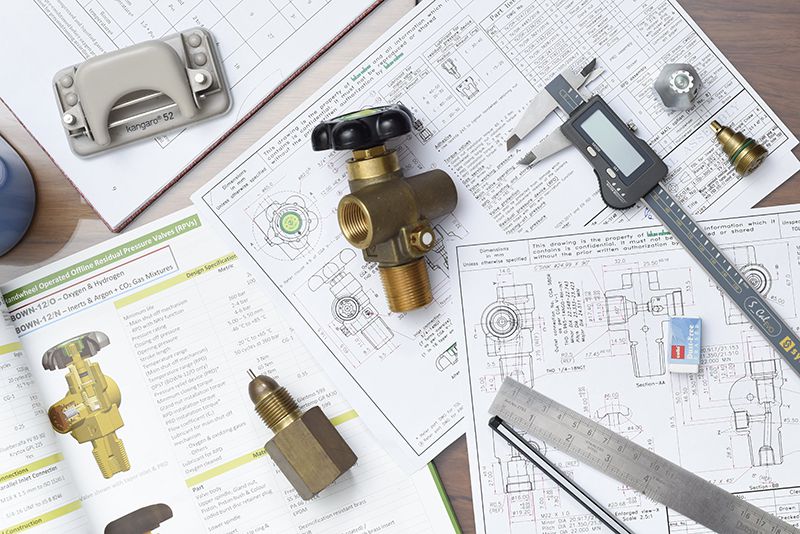

Design

2

2

Forging

3

3

Stress Relieving

4

4

Surface Finish

6

6

Marking

7

7

Chrome plating

8

8

Deburring

10

10

Assembly

11

11

Pressure Testing

12

12