PRDs are Pressure and / or Temperature activated devices equipped on cylinders/cylinder valves to prevent the pressure in a cylinder from rising above a predetermined maximum, thereby preventing rupture of the cylinder in case the cylinder is exposed to fire, high temperature and / or overfilling.

Types of PRD

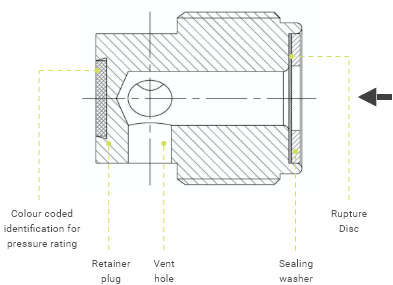

Description

Pressure operated non-reclosing device designed to function by the bursting of a pressure containing disc. Once the disc ruptures, it completely releases the content of the cylinder. It is equipped with colour coded safety for easy identification of its set pressure.

For compressed gas UN cylinder, test pressure of the cylinder is 1.5 times the working pressure of cylinder. For liquefiable gas UN cylinder, test pressure & the corresponding filling ratio is given in P200 of ADR. Test pressure of a DOT cylinder is 5/3 times the working/service pressure.

Markings

- Manufacturer’s identification

- Model No.

- Rated burst pressure : Maximum pressure for which the disc is designed to rupture when in contact with the pressure opening

- Rated temperature : The design temperature at which the burst pressure of the disc is tested

- Flow capacity : The capacity of free air discharged at the required flow rating pressure

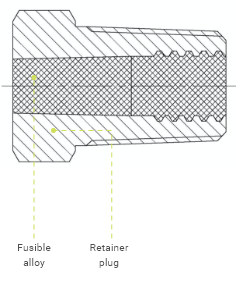

Description

Thermally operated non-reclosing device designed to function by the yielding of a fusible metal at a set temperature. These devices do not protect from overpressurization at temperatures below their melting point. In the event a cylinder is exposed to fire or excess heat, the fusible plug is designed to melt & release the cylinder contents preventing product within the cylinder from creating excessively high pressures, caused by high external temperatures & rupturing the cylinder.

These devices are limited for use up to 500 psig service pressure due to risk of extrusion of the alloy.

- CG-2 plug yields at a temperature between 157°F to 170°F (69.4°C to 76.7°C). Nominal temperature 165 °F (74 °C).

- CG-3 plug yields at a temperature between 208°F to 224°F (97.8°C to 106.7°C). Nominal temperature 212 °F (100 °C).

Markings

- Manufacturer’s identification

- Model No./Part No.

- Alloy yield temperature – Temperature at which the fusible material becomes soft to extrude from its holder to permit the discharge of fluid.

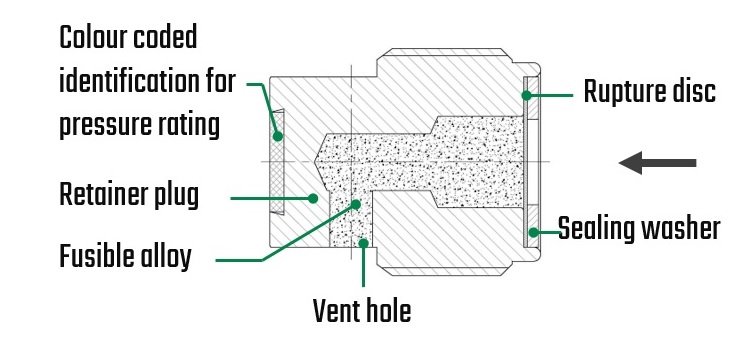

Description

Combination of pressure & temperature operated non-reclosing device consisting of a rupture disc backed by fusible alloy on the atmospheric side of the disc. In case of fire or high temperature, the fusible metal yields & cylinder overpressure is relieved by the bursting of the rupture disc. Both the pressure & temperature requirements of the device must be satisfied for the device to actuate. This device will not protect a cylinder from overpressurization if the fusible alloy is not heated to its yield temperature. The fusible metal prevents premature rupture disc failure from momentary overpressurization & also protects the disc from external corrosion.

- CG-4 plug yields at a temperature between 157°F to 170°F (69.4°C to 76.7°C). Nominal temperature 165 °F (74 °C).

- CG-5 plug yields at a temperature between 208°F to 224°F (97.8°C to 106.7°C). Nominal temperature 212 °F (100 °C).

Markings

- Manufacturer’s identification

- Model No./Part No.

- Rated burst pressure : Maximum pressure for which the disc is designed to rupture when in contact with the pressure opening

- Rated temperature : The design temperature at which the burst pressure of the disc is tested

- Flow capacity : The capacity of free air discharged at the required flow rating pressure

- Alloy yield temperature : Temperature at which the fusible material becomes soft and no longer supports the rupture disc

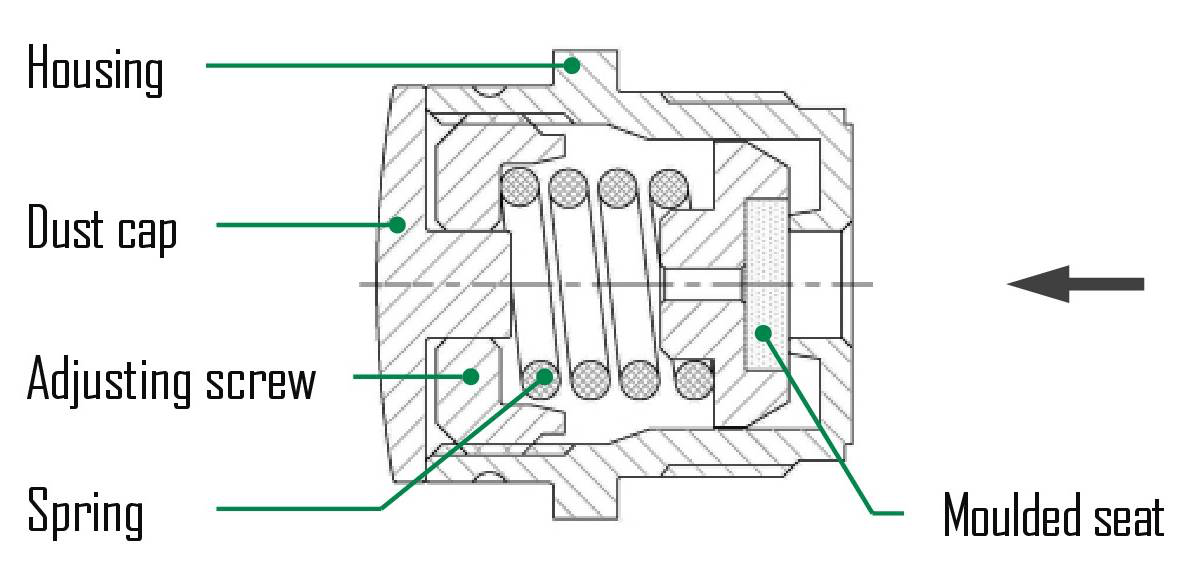

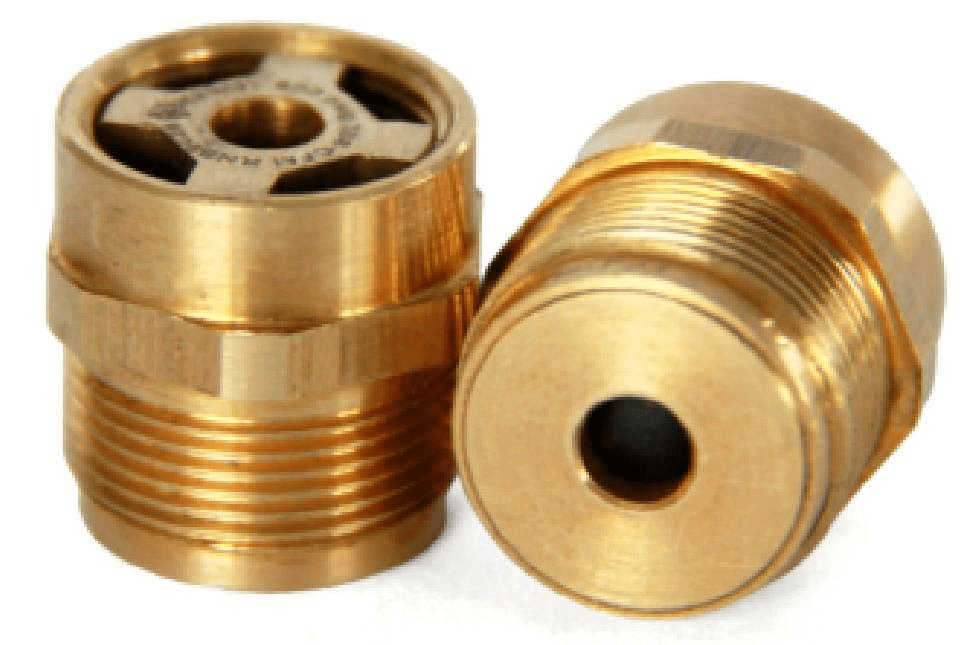

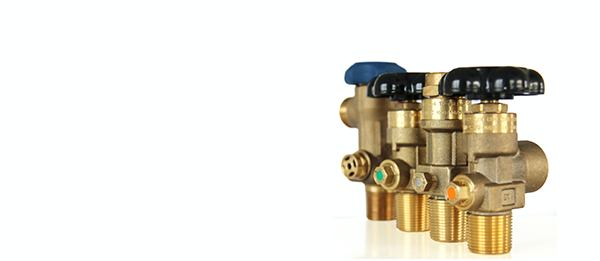

Description

Spring-loaded device designed to relieve excessive pressure & reclose & reseat to prevent further flow of gas or fluid from the container after resealing pressure is achieved. When the cylinder pressure exceeds the pressure setting of the spring in the relief valve, the valve opens to discharge the cylinder contents. Once the cylinder pressure decreases to the Pressure Relief Valve’s (PRV’s) pressure setting, it reseats above the pressure in a normally charged cylinder at 130°F (54.4 °C) after venting sufficient gas to control the internal cylinder pressure. The pressure setting of the pressure relief valve is normally between 75% & 100% of the minimum test pressure of the cylinder.

This device does not protect against rupture of the container when the application of heat weakens the container to the point where its rupture pressure is less than the operating pressure of the device. These devices are limited for use up to 500 psig charging pressure cylinders.

Markings

- Manufacturer’s identification

- Date of manufacture

- Model No./Part No.

- Set pressure : Pressure for which the PRV is set to start-to-discharge

- Rated flow pressure : Inlet static pressure at which the flow capacity of a PRD is measured for flow capacity rating purposes

- Flow capacity : The capacity of free air discharged at the required flow rating pressure